Chip Shortage Automotive India

Chip Shortage Automotive India. Vehicles queue at a traffic light on a hazy morning in new delhi, india, october 16, 2020. The chip shortage is still impacting the automotive industry in 2022, though the good news is this problem is expected to get better as the year goes on.

Researchers at the indian institute of science (iisc) have been collaborating with a semiconductor foundry under the. A global chip shortage has plagued companies from smartphone makers to consumer electronics firms and carmakers, forcing companies including toyota to repeatedly cut production even as raw material costs rise. There are several reasons that contribute to this shortage, one of which is the increasing demand for automotive and consumer goods (most of their parts are driven by electronics).

Researchers at the indian institute of science (iisc) have been collaborating with a semiconductor foundry under the imprint programme of the government of india, which could provide a solution to serious shortage of chips in the automotive industry.

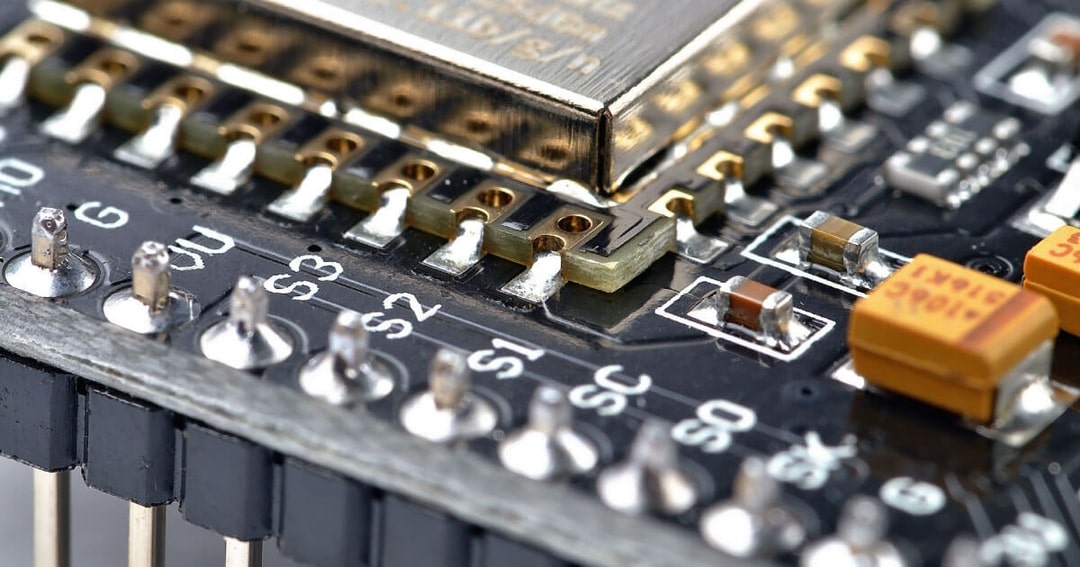

Automotive chips are different from the conventional processor chips used in devices such as smartphones and laptops. Automotive chip s are different from the conventional processor chips used in devices such as smartphones and laptops. Chips to be used for commercial and strategic applications.

A global chip shortage has plagued companies from smartphone makers to consumer electronics firms and carmakers, forcing companies including toyota to repeatedly cut production even as raw material costs rise.

Report according to a report, india's dependency on semiconductor imports is unlikely to decrease amid these unprecedented times. An automotive chip (also referred to as a power asic) needs to handle various tasks simultaneously, including instrumentation,. By 2025, chip shortages and trends such as electrification and autonomy, are expected to drive up to 50 per cent of the top 10 automotive oems 5 to design their own chips.

Researchers at the indian institute of science (iisc) have been collaborating with a semiconductor foundry under the imprint programme of the government of india, which could provide a solution to serious shortage of chips in the automotive industry.

“the shortage is expected to continue for more time as new investments in semiconductors will take a long time,” said kenichi ayukawa, president at society of. The ongoing transition to electric mobility has also worsened the situation. Like the rest of the world, indian automotive manufacturers have also been affected by this shortage significantly.

When chip shortages first shut down automotive production lines in 2021, the semiconductor industry found itself in an unaccustomed spotlight.

The chip and semiconductor shortages have impacted the supply chain of oems, aggressively leading to a decline in the overall business. Like the rest of the world, indian automotive manufacturers have also been affected by this shortage significantly. Research and development in this industry, includes electronic products and embedded systems, generated about us$2.5 billion in revenue.

Iisc technology can address automotive chip shortage.

It also anticipated that the lessons learned from the microchip shortage will further drive automakers to become more technologically savvy. So, from this standpoint, the. The chip shortage is still impacting the automotive industry in 2022, though the good news is this problem is expected to get better as the year goes on.